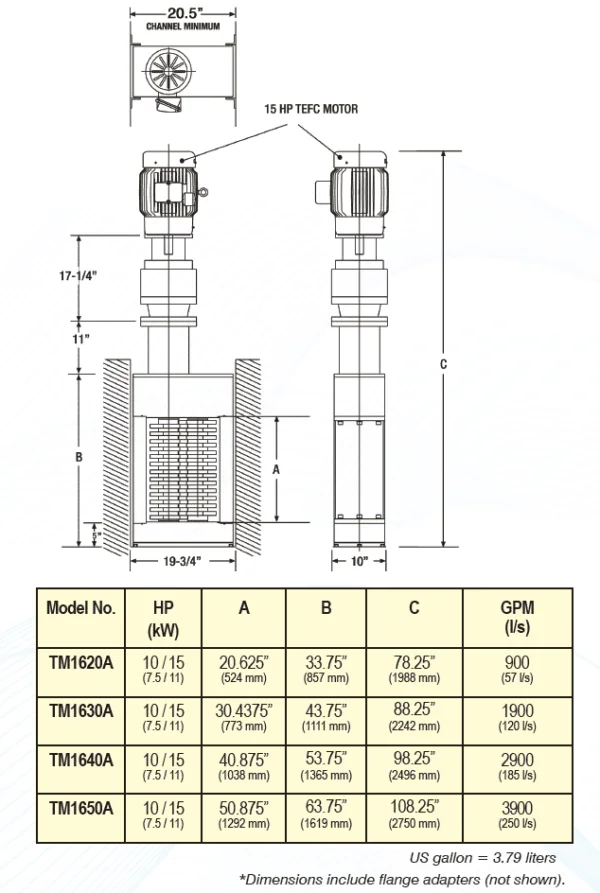

These units can be installed for full or occasional submergence with our unique submersible explosion-proof motor and drive. They can be supplied with support frames or channel frames as well as guide rails to facilitate removal from wet wells. A variety of drive configurations is available to meet most installation requirements including standard electric motors, submersible explosion-proof motors, extended shafts or hydraulic systems

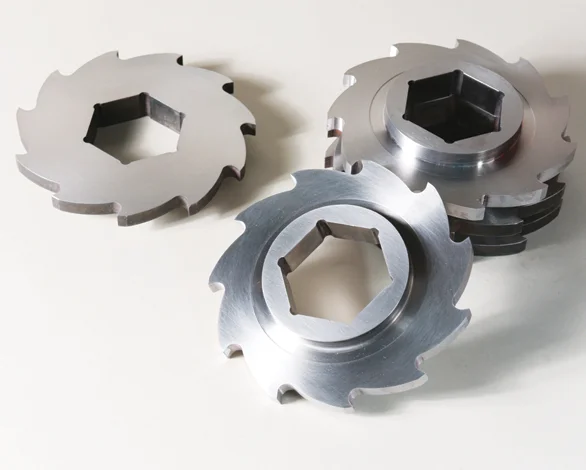

The TASKMASTER® TM1600 employs unique cutter-spacer combo's. These cutting elements combine individual cutters and spacers into high strength elements for high strength and reduced overall components The cutter/spacers are available in a variety of profiles to match your exact application requirement. They are constructed of high strength alloy steel and then hardened and ground. They also available in hardened stainless steel.

The versatile TASKMASTER TM1600 can be configured for liquid channels, wet wells, water inlets or pipeline installations. It can also be used in gravity-fed installations, such as for screenings discharged from a bar screen. Units can be provided with a stand and hopper for a variety of gravity-fed shredding applications.